How Kettering Driveway Contractors Handle Freeze-Thaw

Concrete Driveway Kettering

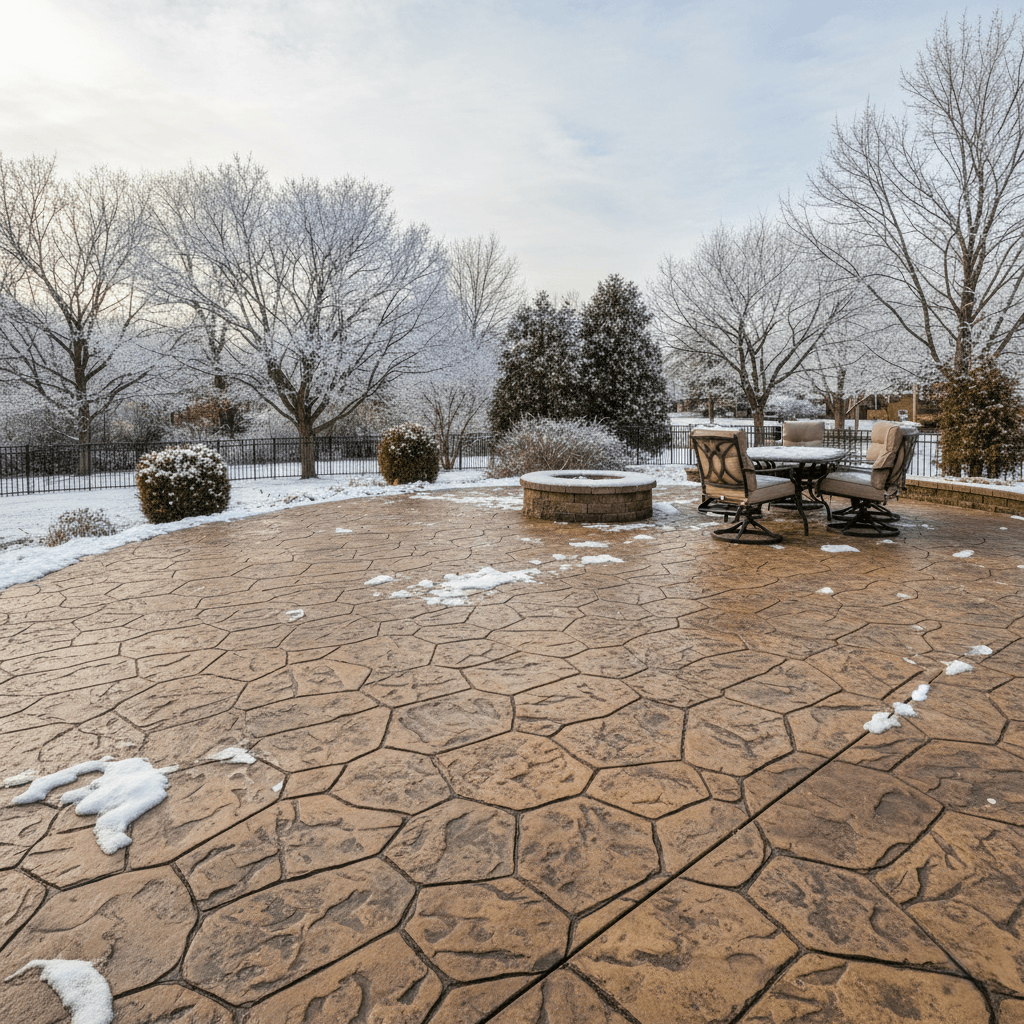

The freeze-thaw cycle of the winter season creates unique challenges for a professional contractor installing a concrete driveway in Kettering. A large portion of the area, including areas like the Fraze Pavilion and residential neighborhoods, experiences extreme temperature changes, which can cause serious deterioration of an exposed concrete surface. A professional contractor will have numerous methods to protect their customers’ driveways from freeze-thaw damage before it happens. If the contractor can use one or more of these methods on your new driveway, you will be assured that the driveway will retain its strength and appearance through even the most difficult winters in Ohio. Understanding how the professional contractor addresses the freeze-thaw issues will allow you to make educated decisions as a homeowner when selecting the best contractor to install your driveway and also when deciding what maintenance should be done on your driveway after it has been installed.

Why Freeze-Thaw Damage is Common in Kettering’s Freezing Weather

Kettering’s climate has perfect conditions for freeze-thaw cycle attacks, which cause poor-quality protected concrete driveways to crumble. When water enters a pore in the concrete and freezes, the water will expand about 9% and build up pressure inside the concrete from the inside out, which breaks down the material. Professional concrete companies understand that Montgomery County gets many freeze-thaw cycles each year, so protection of a concrete driveway is crucial to extend its life.

The problem gets worse when there are constant fluctuations of temperature above and below 32 degrees F. During warmer hours, water will enter micro-cracks, but once the temperature drops to 32 degrees F or less at night, the water will freeze and make the concrete expand again. This continuous expansion and contraction of the frozen water weakens the concrete structure gradually until you have surface scaling, spalling, and ultimately structural failure if no protection is put in place.

Why Your Ohio Concrete Driveway Is Especially Susceptible to Freeze-Thaw Cycles

In addition to freeze-thaw cycles, your concrete driveway in Kettering faces other stresses, such as vehicle traffic, de-icers, and moisture, which can greatly enhance the effects of freeze-thaw cycles. With heavy traffic being present near locations such as The Greene Town Center and residential areas, the potential for freeze-thaw damage starts to occur in the most stressful areas of the concrete driveway. Experienced contractors take all of this into consideration when they formulate their protection plans for the area.

Air-Entrained Concrete: The Best Defense Against Freeze-Thaw Cycles

Experienced driveway contractors use air-entrained concrete as the best way to protect their concrete driveways from freeze-thaw damage in Kettering. Air-entrained concrete has millions of microscopic air bubbles that act as a release valve for the expanding water during the freeze cycles. These small bubbles allow the internal pressure to dissipate and prevent the cracking and structural failure of the concrete.

The air-entraining agents that are added to the air-entrained concrete keep the air bubbles stable throughout the mixing process and evenly distribute them throughout the concrete. Typically, experienced contractors specify an air content of between 4-7% for the best freeze-thaw resistance with minimal impact on the compressive strength of the concrete. This method has been successful in protecting driveways in neighborhoods near Rosewood Arts Centre and surrounding residential communities.

Recommended Amount of Air for Protecting Kettering Driveways

Experienced contractors closely monitor the amount of air in the concrete during the mixing process to ensure adequate protection without diminishing the strength of the concrete. If too little air is incorporated into the concrete, it will leave it vulnerable to freeze-thaw damage; conversely, if too much air is included, it will reduce the compressive strength of the concrete and the surface durability. Quality contractors use specialized equipment to determine whether the correct amount of air was incorporated into the concrete prior to laying the concrete for a driveway installation.

Designing a High-Quality Concrete Mix for Winter Conditions

Experienced contractors select specific mixes of high-quality concrete that are formulated to protect against Ohio’s harsh freeze-thaw conditions. A lower water-to-cement ratio will decrease the permeability of the concrete, thereby limiting how much water the concrete absorbs, which will subsequently limit freeze-thaw damage. Using high-strength concrete with a minimum of 4000 psi compressive strength will increase the tensile strength of the concrete to better handle the internal pressures from freezing water.

Experienced contractors select the right type of aggregates for freeze-thaw resistance and overall concrete durability in Montgomery County’s conditions. Additionally, quality contractors include supplementary cementitious materials (SCMs) in their mixes to increase the density of the concrete and reduce the porosity of the concrete. SCMs will result in a more impenetrable concrete driveway that prevents water from entering the concrete and maintains workability during the installation of the driveway.

Reinforcing Fibers Improve Freeze-Thaw Resistant Performance and Crack Control

Many modern contractors now add synthetic fibers to their concrete mixes to improve the freeze-thaw resistant performance of the concrete and to control crack development caused by the freeze-thaw cycles. Polypropylene fibers dispersed through the concrete will aid in controlling the spread of the cracks that occur due to the freeze-thaw cycles. This additional protection will give homeowners additional peace of mind knowing that their driveway will perform well over time.

Techniques That Experienced Contractors Use to Protect a New Concrete Driveway from Future Damage

Experienced contractors will utilize various specialized installation techniques to minimize the likelihood of future freeze-thaw damage from the initial stages of construction. Ensuring that the subgrade is prepared correctly will promote good drainage directly under the new concrete driveway to avoid standing water accumulation that contributes to freeze-thaw damage. Expertly graded areas will redirect water away from the concrete surfaces and minimize the saturation of the concrete that increases the destruction of the freeze-thaw cycles.

Additionally, expert contractors will follow the proper curing processes to ensure that the newly placed concrete develops to its full strength prior to being exposed to the freeze-thaw cycles. Monitoring the temperature during installation will enable contractors to lay the concrete at the best possible temperature to achieve the highest level of freeze-thaw resistance.

Installation of Correctly Located and Sealed Control Joints

Quality contractors will install control joints to manage the shrinkage of the concrete and to prevent random cracking that would provide avenues for water to penetrate the concrete. The joints should be properly sealed with flexible materials that do not allow water to infiltrate while allowing the concrete to move normally. Properly sealing the control joints is a very important part of a contractor’s freeze-thaw protection plan.

Protection Methods Provided by Penetrating Sealants That Experienced Contractors Will Apply to Your Concrete Driveway

Experienced contractors will apply penetrating sealers that chemically bind with the concrete to create a long-lasting water-repellant barrier. These sealers will prevent the absorption of water that will lead to freeze-thaw damage while still allowing the concrete to breathe. Quality contractors will ensure that the sealant is applied to the entire area and penetrated sufficiently to ensure maximum protection.

Typically, quality contractors will recommend reapplying a sealer to a concrete driveway every 3-5 years based upon traffic exposure and weather conditions near areas such as Indian Riffle Park. Applying a sealer regularly will continue to provide protection from freeze-thaw cycles and extend the lifespan of your concrete driveway significantly. Many quality contractors will also provide maintenance schedules and offer resealing services to protect your investment.

Types of Sealers Used to Provide Freeze-Thaw Protection

Silane and siloxane-based penetrating sealers are the preferred types of sealers that quality contractors will use to provide excellent water repellency without affecting the appearance of the concrete. The chemical reaction between the sealers and the concrete forms a permanent water-repellent barrier deep within the concrete structure. Quality contractors may also use film-forming sealers to provide additional stain resistance in conjunction with freeze-thaw protection.

At Kettering Concrete Solutions, our freeze-thaw protection methods are comprehensive and combine air-entrained concrete, proper mix design, expert installation techniques, and protective sealing systems. As a company with extensive experience serving neighborhoods in Kettering, we are confident that your concrete driveway will receive the special protection needed to withstand Ohio’s severe freeze-thaw cycles for many years to come.