Kettering Concrete Walkways: Poured vs Precast Explained

Concrete Walkway Kettering

Homeowners in Kettering who are planning to install a concrete walkway will need to decide whether they want to use either the poured-in-place or precast method of installing a concrete walkway. Each type has its own benefits for the unique climate and soils of Montgomery County. Contractors working in all the residential areas around Kettering Medical Center, as well as other neighboring areas, know how the unique environmental characteristics of the area impact the function of various types of walkway installation. While poured concrete allows for an ability to design your walkway as you wish and can be designed to blend seamlessly into existing landscape elements, precast walkways provide for quicker walkway installation times and manufacturing quality control. The freeze-thaw cycles found in Ohio’s climate as well as clay rich soils present unique problems for both types of installation methods, therefore it is beneficial to understand the basic differences between these two installation methods so that homeowners can identify the best concrete walkway installation method for their home based on their required performance characteristics, aesthetic needs, cost constraints and desired long term durability.

Poured Concrete Walkway Fundamentals

A walkway made of poured concrete is constructed by creating and placing the fresh concrete mixture on-site, then removing the temporary mold (or “form”) that has been built around it to give the walkway its final shape and configuration. The ability to build an unlimited number of different configurations (curved, wide, narrow) and integrate them with other existing hardscape elements makes this cast-in-place method extremely flexible. All aspects of the poured concrete mix design, placement, and finishing are done by trained professionals who are able to achieve the exact performance characteristics that will allow the walkway to function properly in Kettering’s extreme conditions.

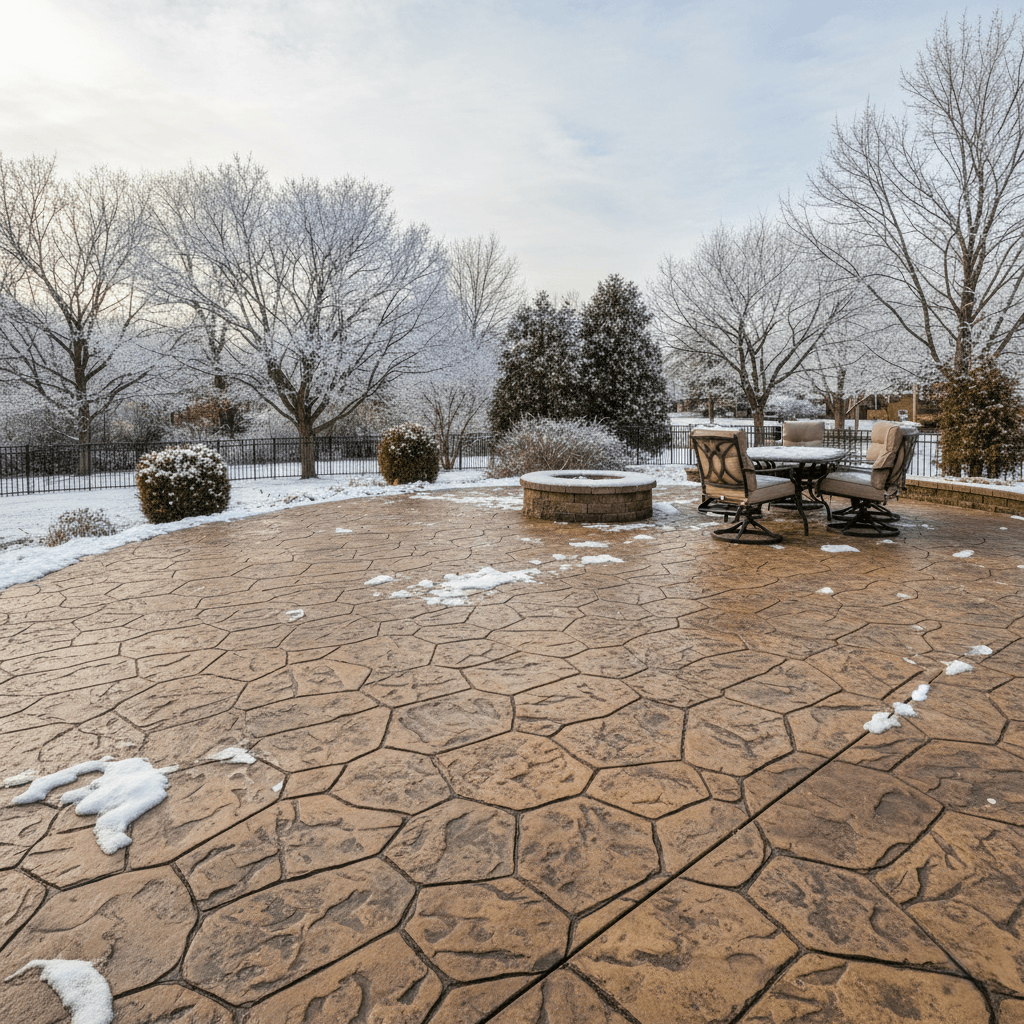

Decorative elements, such as exposing the aggregate, making stamp patterns, and adding color to the concrete, all allow the contractor to create a unique look for each walkway. Additionally, the contractor can choose how thick the concrete is to be placed, what type of reinforcement (if any) is used, and how the finished surface is to be treated to suit specific load and drainage requirements at the site. Each property located in Kettering University’s surrounding neighborhoods benefits from customized solutions to site-specific problems while realizing its desired aesthetics.

Process for Building Poured Walkways

Once the site is excavated, the subgrade is prepared, and the molds are built, the first step in building a poured walkway is to install the reinforcing materials; next, the concrete is poured; finally, the finishers complete their task while the concrete is still workable. This process requires coordination between multiple workers and specialized equipment to produce a professionally acceptable product within the limited timeframe of when the concrete is still workable.

Precast Concrete Walkway Systems

Precast concrete walkway systems use manufactured concrete panels or pavers that were produced in a factory and are delivered to the job site, where they are assembled into the finished walkway system. Since the components were produced under controlled conditions, manufacturers can ensure consistent quality, strength, and dimensionally accurate products. Once the manufacturer produces the precast units, the installer sets each unit onto a bed of leveled sand with adequate space for water to drain and proper joint spacing for maximum performance.

Manufacturing facilities can also create many different finishes, textures, and colors that are often difficult to reproduce in the field with a poured walkway. Precast units can simulate natural stone, brick, and even custom designs and patterns while offering superior durability and weather resistance over traditional poured walkways. Due to the controlled curing conditions in the factory, the cured strength of precast units will generally be greater than field-cast alternatives found in Montgomery County installations.

Precast Installation Method

Installing precast concrete walkway systems starts with preparing the site for installation. This typically includes excavating, laying down the base material, and leveling the area to a precise grade so that the precast units can be placed correctly. Then, using specialized equipment, the contractor places each precast unit onto the leveled base while maintaining proper alignment and drainage slope. This orderly procedure allows for rapid installation, with the finished product being usable immediately after completion.

Comparison of Durability and Performance

Both poured and precast concrete walkway systems will provide a high level of durability if properly installed and maintained in Kettering’s harsh environment. A poured walkway creates a single, monolithic structure without joints that provide possible failure points; however, the possibility exists for random cracking due to soil movement or thermal expansion/contraction stress. Properly designed and installed, the risk of failure is minimized by the inclusion of reinforcement and the strategic placement of control joints.

Precast systems distribute stresses across multiple units and their associated joint systems that accommodate the movement of the units without causing damage to individual components. While the joints of precast systems must remain intact in order for the system to last long-term, the failure of a single joint can allow for the movement of the adjacent units and potentially cause additional damage to the surrounding area. Properties in areas near David’s Cemetery and the surrounding neighborhoods will benefit from a professional evaluation to determine which system is better suited to their specific soils and intended usage.

Freeze-Thaw Resistance

Both poured and precast concrete walkway systems require special attention to achieve good freeze-thaw resistance. Poured systems require the designer and finisher to provide a proper mix design and finishing technique. Precast systems benefit from the controlled manufacturing conditions used to make the units. In either case, the inclusion of air entrainment and the quality of the materials used in the manufacture of the units will greatly contribute to the system’s ability to withstand the severe winter conditions found in Ohio. Professional contractors know the importance of achieving long-term weather resistance for both types of installations.

Cost Comparison and Budget Implications

The average cost of installing a poured concrete walkway ranges from $6 to $12 per square foot, depending on the complexity of the design and the decorative finishes required. Installing basic systems costs less money than those that require decorative elements such as stamping or coloring, and the cost of labor is a significant part of the overall cost of a poured concrete walkway because of the skilled nature of the labor involved and the time-consuming nature of the installation process.

The average cost of installing a precast concrete walkway system is from $8 to $20 per square foot, depending on the decorative finishes of the individual units. While transportation and installation equipment costs can be added to the total cost, the reduced labor time required for most precast installations usually offsets these added costs. Large-volume purchases of precast walkways may provide cost savings to developers and builders of large residential developments in Fairmont High School and the surrounding areas.

Long-Term Benefits

Both poured and precast concrete walkways provide excellent long-term value through their durability and low maintenance requirements. For poured walkways, the long-term value is achieved through their ability to withstand the test of time, provided that they are properly installed. For precast systems, the long-term value is realized through the ease of replacing damaged individual units without disrupting the rest of the walkway system. Professional maintenance recommendations will assist homeowners in maximizing the long-term value of whichever type of walkway system was installed.

Timeline and Process Differences Between Installation Types

While a poured concrete walkway can take anywhere from 3-7 days to install, depending on the complexity of the design and the weather conditions, a precast concrete walkway system can be installed in 1-3 days, depending on the amount of precast material that must be set. Because the precast units are manufactured in a factory before delivery to the job site, the need for weather-related scheduling is eliminated, except for the time required to transport the units to the site and prepare the site for the installation of the precast units. The quicker installation time of precast walkways minimizes disruptions to daily household activities and yard maintenance throughout the construction period.

Seasonal Installation Timeframes

Due to the fact that there is no curing process required for precast concrete walkways, they can be installed at almost any time of the year, regardless of the weather conditions. Poured walkways, on the other hand, can only be installed when the weather cooperates enough to permit the proper curing and finishing of the walkway. Professional contractors will advise clients as to the optimal timeframe for installation of each type of walkway, based on local weather patterns and client requirements.

Design Flexibility and Aesthetic Choices

One of the greatest advantages of poured concrete walkways is the virtually unlimited design flexibility they afford. Poured walkways can be created in any shape, curve, and/or size to fit the unique needs of each homeowner and site. Decorative techniques can be incorporated into the placement of the concrete to enhance the beauty of the walkway and to create seamless transitions to other hardscape features, such as patios, steps, etc. The ability to customize a poured walkway to meet the specific aesthetic and functional needs of each homeowner is unmatched by precast systems.

Precast walkway systems provide a great deal of design flexibility, given the constraints of the manufacturing process. Many different textures, colors, and patterns are available from various suppliers to create a wide variety of attractive walkway designs. Individual units are of fixed sizes; therefore, the creation of attractive walkway designs depends on the creativity of the designer/installer and the use of border treatments and other design elements to create visual interest. Homeowners living in areas near Rosewood Arts Centre will find the vast array of precast walkway options to be beneficial in creating the desired aesthetic look for their homes while minimizing the construction time.

Customization Options

Poured concrete offers full customization of the dimensions, slope, and decorative elements of the walkway to satisfy the needs of each particular project. Precast walkways offer customization through the selection of individual units, the design of the pattern of the units to be used, and the design of the borders to surround the walkway. Professional contractors will help homeowners determine what customization options will meet their needs and budgetary constraints.

Maintenance Needs and Repair Options for Walkways

Poured concrete walkways require periodic sealing and crack repair to maintain their appearance and functionality. Repair work often involves matching the existing concrete and may require treating a larger area of the walkway to effectively repair the issue. Professional maintenance programs will help to identify problems early in the life-cycle of the walkway, prevent the deterioration of the walkway, and reduce costly repairs.

Precast concrete walkway systems require the same type of maintenance as poured concrete walkways, with the exception that the individual damaged units can be easily replaced without damaging the remaining units. Therefore, repair work on damaged individual units is relatively inexpensive and simple to accomplish. Routine maintenance includes cleaning and lubricating the joints, checking the levelness of the individual units, and occasionally adjusting the levelness of the units to maintain proper drainage and safety.

Professional Maintenance Programs

Both poured and precast concrete walkways benefit from professional maintenance programs that include routine inspections and preventive treatments, as well as timely repairs. By identifying potential problems early in the life-cycle of the walkway, expensive repair work can be avoided. Professional contractors will provide maintenance recommendations that are specific to the type of installation that was performed and the local conditions of the site.

Compliance with Local Codes and Installation Standards

Building codes and accessibility requirements in Kettering apply to both poured and precast concrete walkway installations. There are specific standards for the slope, width, and texture of the surface. Professional contractors will ensure compliance with local building codes and ADA accessibility requirements, if applicable, and obtain any necessary permits for the project, depending on the scope of the project and jurisdiction within Montgomery County.

Professional Installation Standards

Regardless of whether a poured or precast concrete walkway is selected, professional installation is essential to achieving the highest level of quality and performance that meets the local standards and expectations. Quality contractors will provide warranty and support services to protect the investment of the homeowner. Professional installation will ensure that the correct procedures are followed, quality materials are used, and local building codes are complied with.

At Kettering Concrete Solutions, our goal is to assist homeowners in selecting the right walkway system for their specific needs and site conditions. We specialize in both poured and precast concrete walkway systems and will evaluate the requirements of the project, the budget, and the aesthetic desires of the homeowner to recommend the most suitable concrete walkway system to provide long-term value and performance in the challenging environment of Montgomery County.