How Local Concrete Contractors Estimate Flatwork in Kettering

Concrete Flatwork Kettering

Understanding how a professional contractor estimates your flatwork is important, as it will give you the knowledge and ability to make an educated decision regarding your project. Contractors in Kettering who have experience estimating concrete flatwork use a structured process that considers costs of materials, labor, site condition and local market conditions. The process used by experienced professionals in the industry provides fair and accurate pricing for each job while protecting both the contractor and the homeowner. The process also includes all aspects, from simple square footage of the area to be covered, to all site preparation requirements, and seasonal changes in the cost due to Ohio’s climate and weather conditions.

Flatwork Estimating Essentials

Flatwork estimating starts with an evaluation of the job site and all aspects of the project. The contractor will look at the nature of the project (driveways, patios, sidewalks, etc.) and the specifics of the job. Based upon those specifics, the contractor will decide how much of each piece is needed to get the project done. The amount of each piece needed is based on how it will perform under the conditions of the job.

All estimating begins with an accurate count of all the pieces involved in the project. An experienced estimator will take exact measurements of the length, width, and desired thickness of each section of the project to calculate the total number of square feet and cubic yards of concrete required for the project. In addition to the concrete, there will be additional materials such as reinforcing steel, wire mesh, expansion joints, and forming lumber, which the estimator will also account for in the estimate. Most estimators have established relationships with several different suppliers so they can accurately price materials and know if the materials are available when needed.

Factors That Influence the Price of Materials

The average cost of residential concrete in Ohio ranges from $130 to $155 per cubic yard. The price of the concrete depends on the strength of the concrete and the distance the concrete has to travel from the plant to the job site. Contractors who are located close to a concrete plant in Dayton tend to have lower costs for their concrete compared to contractors who live farther away. The cost of transporting the concrete varies greatly depending on the distance the truck has to travel. On average, the cost of transportation is between $150 and $300 per load and depends on the size of the truck and the distance traveled.

Seasonal Pricing Fluctuations

Prices fluctuate seasonally based on the needs of the contractor and the weather conditions in the area. During the winter months, contractors can expect to pay less for the concrete because there is less demand for it. However, they may expect to pay more for labor because of the colder temperatures and the need for heaters to keep the concrete warm enough to set properly. Spring and fall are usually the best times to do flatwork in terms of weather and prices.

Location-Based Cost Fluctuations

In terms of location-based cost fluctuations, the cost of labor in Kettering reflects the regional economy and the supply and demand of skilled workers. Experienced flatwork crews charge anywhere from $45 to $65 per hour for their services, while specialized decorative work may cost $60 to $85 per hour. The cost of the labor is inclusive of the benefits, insurance, and overhead costs of the contractor.

Permits and Fees

Building permits and associated fees are another cost that contractors include in their pricing structure. Permit fees for residential flatwork in Kettering usually range from $75 to $200 and depend upon the scope of the project. Contractors who are familiar with the permitting process in Kettering can help expedite the process and save clients money in the long run.

On-Site Evaluation And Preparation Costs

An effective way to avoid surprise costs on-site is to conduct an initial, thorough evaluation of the site. This includes evaluating the condition of the site, the soil conditions, drainage requirements, and the ability to access the site. By identifying potential issues early on, contractors can develop a plan for addressing them, which can help eliminate surprise costs.

Preparation Requirements

Depending on the type of soil and the conditions at the site, preparation requirements can vary greatly. If the site has clay-heavy soil, the contractor may need to add additional base rock and possibly drainage solutions. Sandy soil, which is found in many parts of Kettering, allows for good drainage; however, it may require compaction to create a stable base for placing concrete.

Water Flow Issues

A thorough drainage analysis is critical to preventing future water-flow issues that can compromise the performance of the concrete. The contractor should evaluate the flow of water at the site, identify any low points, and determine the slope of the ground to ensure that the water flows away from the house and does not collect around the edges of the concrete.

Accessibility And Logistics

Another key consideration in developing a pricing structure is the accessibility of the site. Sites that are easily accessible to trucks allow for direct placement of concrete, while sites that are not easily accessible may require the use of pumping services, wheelbarrows, or other specialized equipment that can increase labor costs and time required to complete the project.

Access To Street And Distance To Job Site

The distance from the street to the job site will also have an effect on the cost of materials placed. Jobsites that are located farthest from the street may require the use of pumping services or manual placement of materials that will increase the cost of the materials placed.

Labor Costs

Labor accounts for 40 to 60 percent of the total cost of a flatwork project, making it essential for contractors to estimate labor costs correctly to stay profitable. When determining the correct amount of labor to allocate for a project, contractors will consider several factors, including the difficulty of the project, the weather, and the efficiency of the crew.

Time Required Per Square Foot

The time required to complete a flatwork project will vary depending on the specifications of the project, the size of the crew, and the equipment being used. Typically, a basic flatwork project will require a crew of two to four people working six to ten hours per thousand square feet of concrete. More complex jobs, such as those that involve decorative work, may require larger crews and more time, increasing labor costs.

Types Of Crews

Experienced contractors employ crews with varying skill levels at different wage rates. Lead finishers are paid more for their expertise in producing high-quality surface finishes and textures, while entry-level laborers earn lower hourly wages for performing tasks such as material handling and basic preparation.

Decorative Labor Costs

The cost of decorative labor can double that of basic broom-finished surfaces. Decorative labor costs are determined by the level of expertise and time required to produce a high-quality decorative finish. Contractors must adjust the composition of their crews and the time allocated for labor according to the specifications of the job to accurately price the project.

Weather And Time Constraints

Contractors in Ohio must contend with extreme temperatures and humidity, creating weather-related challenges for flatwork projects. Extreme cold requires added protection measures, heating of materials, and extended curing time. This increases labor costs by 15 to 25 percent during the winter months.

Heat Creates Challenges Too

While extreme cold creates challenges for flatwork projects, hot weather creates its own challenges, including rapid setting times for the concrete and increased water content. Contractors may choose to work during cooler morning hours or provide shade structures to protect workers and mitigate the effects of hot weather on productivity and labor costs.

Pricing Variables

Variables that Affect Pricing of Flatwork Projects

Pricing Variables for Driveway Projects

For most driveway projects, the cost is between $8 and $15 per square foot for standard concrete, depending on the thickness of the concrete, the amount of reinforcement used, and the finish specified by the client. When recommending the type and quantity of reinforcement, contractors must evaluate the type of soil on the job site and the expected weight of vehicles traveling on the driveway.

Reinforcement Costs

Wire mesh is commonly used as reinforcement and adds $0.50 to $1.00 per square foot to the cost of the project. Rebar reinforcement is more expensive and typically costs $1.50 to $2.50 per square foot. Concerete contractors will recommend the amount of reinforcement based on the soil conditions and the expected weight of the vehicles, rather than the minimum amount of reinforcement required by code.

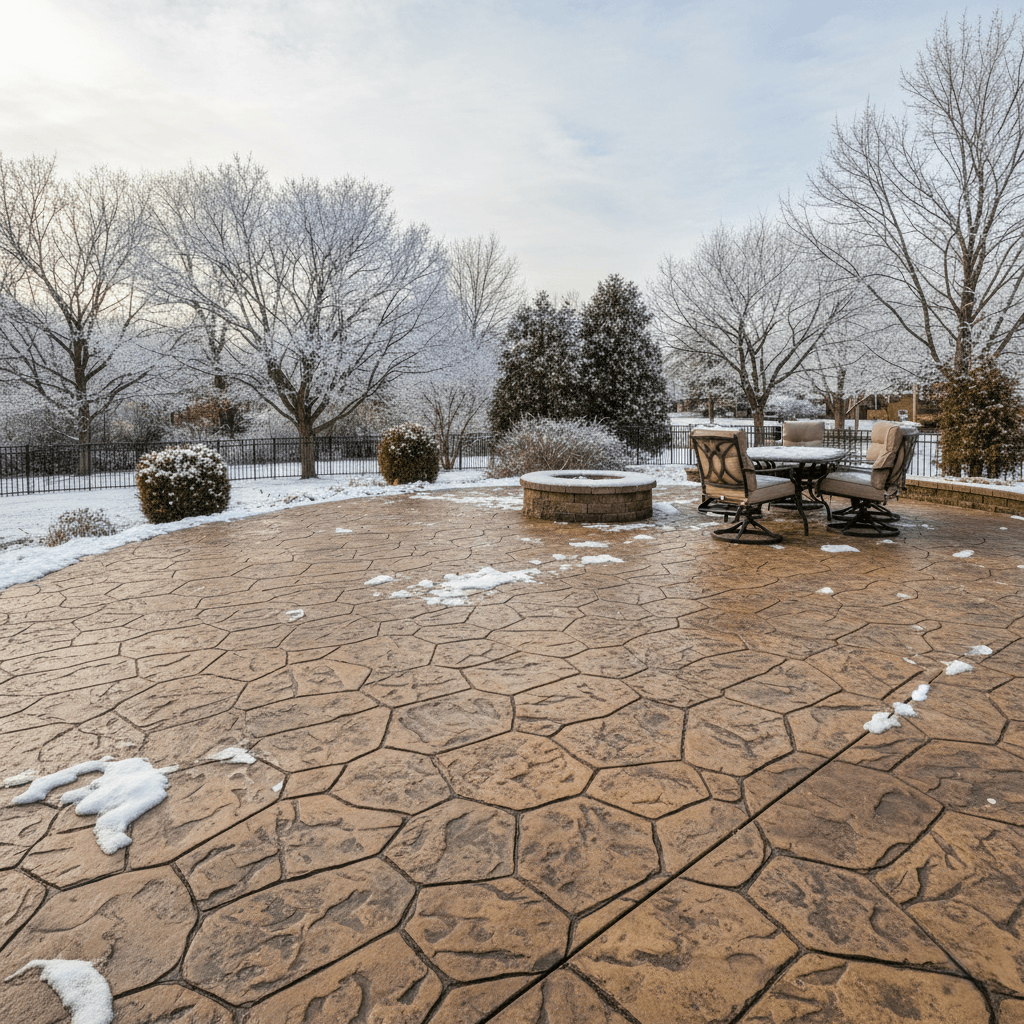

Pricing Variables for Patio and Walkway Projects

The cost of patio projects can vary widely depending on the specifications of the project and the type of finish specified by the client. Standard patio projects typically cost between $6 and $12 per square foot of standard concrete. Decorative finishes can increase the cost of a patio project by as much as $15 to $25 per square foot.

When designing walkways, contractors must consider several factors, including ADA compliance, proper slopes, and integration with existing landscaping. Depending on the specific requirements of the walkway, contractors may have to use specialized forming techniques or place multiple layers of concrete to meet the requirements of the project. Both of these factors can increase the labor costs and the time required to complete the walkway project.

Estimating Software

To improve the accuracy and speed of the estimating process, modern contractors use specialized software designed specifically for estimating flatwork projects. The software uses digital measurement tools, aerial photographs, and automated calculation capabilities to improve the accuracy of estimates and provide detailed breakdowns of the costs for the customer to review.

The software integrates current material pricing, local labor rates, and historical data from past projects to generate accurate and timely estimates. Additionally, the software allows contractors to rapidly analyze multiple options and provide their customers with alternative options to fit within their budgets.

Measurement Techniques

Before visiting the job site, satellite imaging and digital measuring tools allow contractors to provide preliminary estimates of the cost of the project. While the final measurements are still required to be taken physically, these tools allow contractors to provide a rough idea of the cost before visiting the job site.

Drone technology provides a detailed aerial view of the job site. Contractors find drone technology particularly useful when estimating large or hard-to-reach job sites. Drone technology is especially beneficial when estimating large commercial projects or residential projects with limited access to the job site.

Warranty Considerations

When developing a pricing structure for flatwork projects, contractors must consider the warranty requirements of the job. In addition to providing a quality product, contractors must also provide quality control measures and warranty coverage to protect themselves against costly callbacks and to protect their reputation.

These measures can include material testing, proper curing of the concrete, and inspections to ensure that the work meets the standards of the contract. Contractors who provide these measures and include them in the pricing structure of the project demonstrate to their customers that they are committed to providing quality products and services.

Insurance Costs

As part of their pricing structure, contractors must also account for insurance costs. Insurance premiums typically range from 3 to 5 percent of the total project cost. These premiums cover both the contractor and the homeowner against liability and damage to property.

Performance Bonds

Additionally, contractors may be required to post a performance bond to secure the payment of the subcontractor. Performance bonds typically cost between 1 and 3 percent of the total project cost. While this may increase the cost of the project initially, the performance bond ensures that the contractor completes the project as agreed.

Profit Margin

Finally, contractors must also include a reasonable profit margin in the pricing structure of the project to remain profitable. Profit margins typically range from 10 to 20 percent of the total project cost, although this percentage can vary depending on the risk of the project, the local market conditions, and the contractor’s business model.

Equipment Costs

Concrete placement and finishing require specialized equipment that contractors must purchase, maintain, and replace periodically. Contractors can spread out the costs of equipment ownership through hourly equipment rental rates or by incorporating the costs of the equipment into the overall pricing structure of the project.

Equipment rental rates vary based on the requirements of the project. Small projects may only require a few hand tools and a small mixer, whereas larger projects will require larger equipment, such as concrete trucks, pumps, and power finishing equipment that can increase the costs of operating the equipment and therefore the cost of the project.

Market Conditions

In Kettering, the competitive environment among contractors influences pricing structures and estimation methodologies. Experienced contractors strive to strike a balance between providing competitive pricing and quality service to establish and maintain their market positions while ensuring project profitability.

The demand for contractors’ services is affected by market conditions. High-demand periods can cause contractors to charge premium pricing, while slow-demand periods present opportunities for contractors to negotiate pricing. Understanding the dynamics of the market helps homeowners time their projects to maximize value.

Identifying Value Engineering Opportunities

Experienced contractors identify opportunities for value-engineering that can reduce costs while maintaining the quality of the project. One method of reducing costs is by modifying the specifications of the project. Another method is to phase the construction of the project.

Substituting materials or modifying specifications can significantly reduce the cost of materials and, therefore, the overall cost of the project. Contractors who have extensive experience in the industry can suggest substitutes for materials that will maintain the performance characteristics of the original material, but at a lower cost.

Obtaining Accurate Estimates

Obtaining accurate estimates requires that the contractor have sufficient information about the project and that there is open and honest communication between the contractor and the homeowner. Providing the contractor with the necessary information regarding the specifications of the project, the accessibility of the job site, and the timelines of the project will enable the contractor to provide an accurate estimate that includes no hidden costs or unexpected charges.

Obtaining Multiple Estimates

Obtaining multiple estimates from qualified contractors provides the homeowner with a basis for comparison to ensure that he is receiving competitive pricing. However, obtaining very low bids may indicate that the contractor is inexperienced, has insufficient insurance, or does not fully understand the requirements of the project. All of these factors may lead to problems that result in additional expense.

Warning Signs in the Estimating Process

There are several warning signs that a homeowner should watch for during the estimating process. They should look for written estimates that detail all of the costs associated with the project, including materials, labor, and other costs. They should also look for estimates that require large upfront payments or lack detail.

Professional contractors visit the job site before providing estimates and ask numerous questions to ensure that they have a clear understanding of the specifications and expectations of the project. Homeowners should beware of estimates that are developed without a site visit or are based solely on limited information. These types of estimates will likely be inaccurate and may lead to disputes down the road.

Timing and Scheduling

Both the timing of the project and the weather play a role in determining the cost of flatwork projects. Peak demand occurs during the spring and fall when the weather is ideal for outdoor work. During these periods, contractors typically charge premium pricing and have longer lead times.

Projects undertaken during the winter months may be priced competitively, but may require the contractor to implement special techniques and materials to accommodate the colder weather. Projects completed during the summer may encounter heat-related issues that may require the contractor to implement modified schedules or provide additional protective measures for the workers.

By understanding the systematic approach that local contractors follow to estimate concrete flatwork, homeowners can make informed decisions and budget accordingly. At Kettering Concrete Solutions, we apply these tested estimating methods with transparency in pricing and explanation to ensure our customers clearly understand what they are purchasing and the rationale behind each cost component, to ensure the successful completion of their project.