Kettering Concrete Flooring for Garages & Workshops

Concrete Flooring Kettering

Concrete flooring solutions are essential to making average garages and workshop areas into both useful and aesthetically pleasing properties, which will ultimately add value to a home. Homeowners have many different ways to protect and improve their existing concrete floors using modern coating products available today from Kettering. Epoxy-based floor coatings, polished concrete, and other specialty coatings provide a durable protection from vehicle fluid spills and chemical damage from common tools, as well as high traffic and wear and tear. Knowing the benefits and best uses for the most popular types of flooring will help you select the one that will meet your particular needs and be the most effective choice.

Understanding Your Concrete Flooring Options

The modern concrete floor is much more than just painted-on floor coverings. The advanced coating systems are designed as a barrier to protect against chemical damage, staining, and heavy wear and tear, and are available in a variety of attractive finishes. Each system has its own benefits, which depend on how you plan to use your floor space, your budget, and how you want to decorate your floor.

Proper surface preparation is important to the long-term performance of whatever system you choose to put down on your floor. Whether it’s cleaning the surface, repairing cracks, or creating the right surface profile to help the coating adhere, all of these steps will contribute to a successful application. In addition, hiring a qualified installer will help you meet the manufacturer’s specifications for the product you have purchased and help extend the life of the coating.

Epoxy Coating Systems

Two-part epoxy systems are the most commonly used in residential garages and workshops. When combined, the resin and hardener create a very strong and chemical-resistant surface that can withstand the chemicals found in automotive fluids, salt, and other types of mechanical damage. High-quality epoxy coatings also make cleaning up after your projects easy. Because there are so many different color options available, along with decorative flakes, you can customize the look of your epoxy-coated floor to fit your personal style or to match your house exterior. Slip-resistant additives can be added to make the floor safer in slippery situations. Depending on the quality of the application and the care given to the floor, properly applied epoxy systems can last 10 to 15 years with very little maintenance.

Polished Concrete Solutions

A polished concrete floor is a great way to get a beautiful, eco-friendly finish out of your existing concrete slab. By using diamond grinders and polishers, you can create a highly polished, reflective surface that improves the amount of light that enters the space and gives your floor a beautiful sheen. A polished concrete floor is especially good for workshops close to Delco Park and in the surrounding residential areas. Densifiers can be applied to the surface to increase the hardness of the surface and reduce dusting. There are multiple polishing stages to achieve the level of shine you want, from a flat finish to a high-gloss finish. Once a polished concrete floor is completed, it requires little maintenance to keep looking good.

Specialized Coating Applications

Polyurea Floor Coatings

Polyurea systems have many benefits and features, including fast drying times and exceptional flexibility. Polyurea systems are also single-component systems that are resistant to hot-tire pickup, chemical staining, and ultraviolet (UV) degradation. They can usually be applied in a day and allow you to immediately return to your garage or shop. Polyurea systems are ideal for high-traffic shops and multi-use garage spaces due to their extreme abrasion resistance. Their extended pot life allows for a slower and less stressful application process compared to traditional two-part epoxy systems. While cost may be a factor to consider when selecting a coating system, the enhanced performance characteristics and ease of application may outweigh additional cost.

Concrete Staining and Sealing

Staining and dyeing concrete uses acid stains and water-based dyes to create colored finishes that still show the texture of the original concrete. This is a good option for homeowners who wish to give their garage or workshop a decorative touch without applying a thick coating. After being stained or dyed, the surface must be sealed to protect it from wear and staining. Many color combinations and techniques can be used to create unique looks that cannot be achieved with solid coatings. If the job is done correctly, the stain will be evenly distributed, and the sealer will adhere properly to the surface. To keep the color and protection at its best, the sealer should be reapplied periodically.

Selecting the Best System for Your Garage Use

Your garage’s use pattern greatly influences what coating system you should choose. For example, daily car storage will have different performance requirements than infrequent use as a workshop. For garages where heavy equipment and tools are stored and used regularly, greater impact resistance is needed than for garages that are primarily used for storing cars and equipment.

When choosing a coating system, you should also consider how the system will react to the chemicals you use in your garage,e such as automobile fluids, cleaning products, and solvents. Two-part epoxy systems and polyurea systems are more chemically resistant than polished concrete or stained floors.

Budgetary Limitations and Performance Characteristics

Many factors will go into determining which coating system you ultimately decide to apply to your garage floor. One of the most significant will be your budget and the performance requirements you expect from the system. Other factors may include the overall design of your garage or workshop, the number of people who will be using it, and the total square footage of the floor.

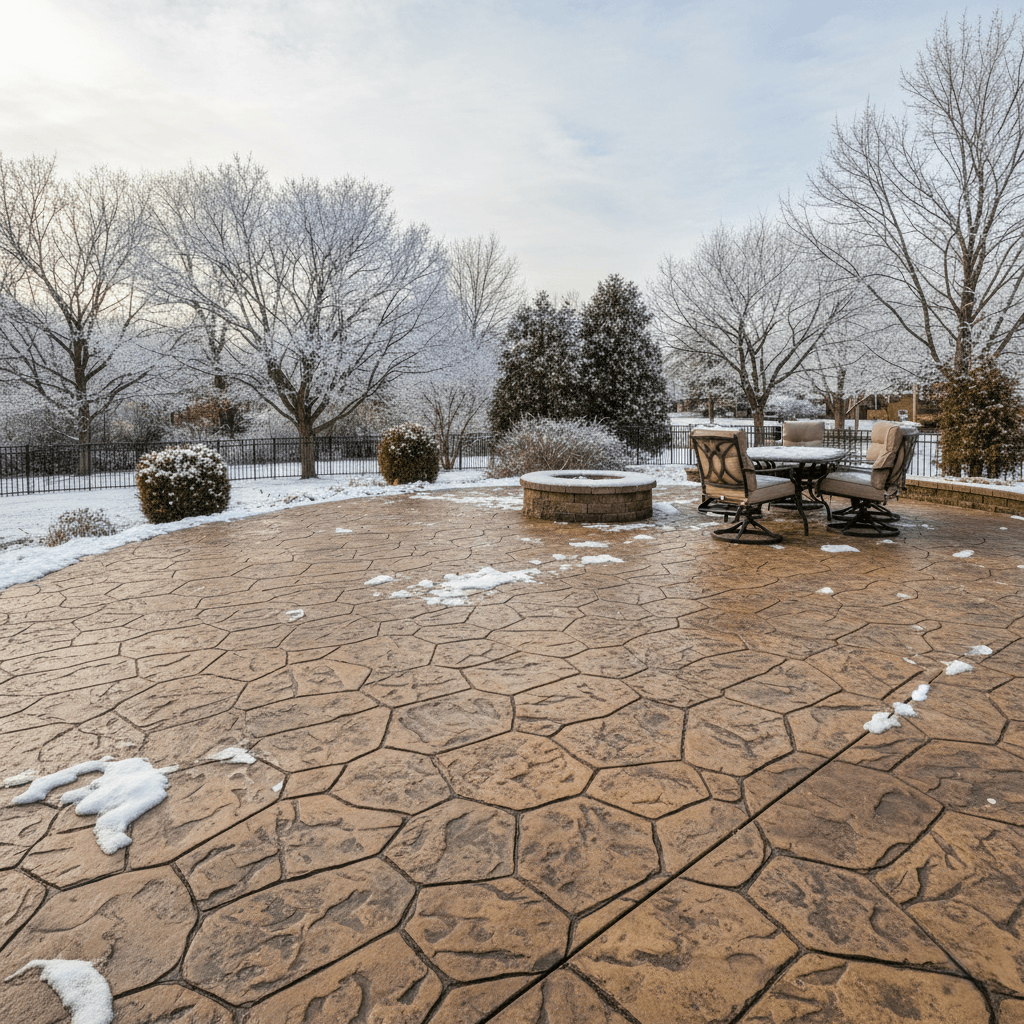

Seasonal Temperature Fluctuations in Kettering

Kettering, Ohio, experiences a freeze-thaw cycle that affects the performance and longevity of a concrete floor. Preventing water from penetrating the concrete and causing damage to the coating is essential. Using chemical-resistant coatings will protect your floor from damage caused by salt and de-icers from your vehicle.

Professional installation will take into consideration temperature swings and schedule the application accordingly to optimize the results of the coating. The correct coating system will stretch to accommodate temperature swings and will not crack or separate from the concrete.

Preparation Requirements for the Surface

To ensure a successful application of a concrete floor coating system, preparation of the surface is critical. All previous coatings, stains, and contaminants must be removed prior to the new system application. Either mechanically grinding or using acid to etch the surface will create the correct surface profile for the coating to adhere to.

Moisture testing is required to prevent coating failures that occur from hydrostatic pressure or excessive moisture in the air. Repairing cracks and sealing joints will also prevent coating failures. A professional preparation will ensure a uniform substrate condition throughout the application area.

Safety and Environmental Considerations

Most modern coating systems are formulated with low VOCs (volatile organic compounds), thus reducing the environmental impact and odor associated with the installation process. Proper ventilation during the application process will protect both the installers and the homeowner. Slip-resistant additives will increase safety in wet conditions without affecting the aesthetic appeal of the coating system.

If you have old houses with lead paint, the contractor must have proper certification and follow EPA guidelines for removing lead paint safely.

Installation Process and Timeline

Typically, a professional installation will take anywhere from 2 to 3 days, depending on the complexity of the system and the amount of time allowed for each coating layer to dry. The largest portion of this time will be spent preparing the surface, and this preparation will directly affect the outcome of the coating. Weather conditions will also play a large role in scheduling and curing the coating.

Re-coats will have specific re-coat windows to ensure that the coats are properly adhering to each other. The length of time that the coating takes to fully cure varies depending on the type of coating. Some coating systems will allow foot traffic after a few hours, while others may need a few days to fully cure.

Quality Control and Inspection

All professional contractors will follow quality control measures throughout the installation process. An inspection of the surface preparation will confirm that the surface is prepared properly and clean enough for the coating to adhere to. Each stage of the coating process will be inspected to ensure that the coverage is sufficient and that the coating is properly applied.

An inspection of the finished floor will include adhesion testing and a visual assessment of the finish. Any defective workmanship or premature coating failure will be covered under a manufacturer’s warranty. Documentation will also provide a record of the coating process and maintenance requirements for future maintenance.

Maintenance and Long-Term Performance

Once a quality concrete floor coating system has been installed, it will require little to no maintenance. Occasional sweeping and mopping will keep the floor looking like new and prevent any abrasive materials from wearing away the coating. Cleaning up any spills immediately will also prevent staining and damage to the coating.

Regular inspections will identify any minor problems before they become major ones requiring extensive repairs. Proper maintenance will also extend the life of the coating system and continue to protect the floor. Performing simple maintenance tasks now will save thousands of dollars in replacement costs later.

Repair and Refinish Options

Small damaged areas can usually be repaired by using the same type of materials that were originally used. Larger damaged areas may require partial or complete re-coating, depending on the type of coating system used and the extent of the damage. A professional assessment will determine the least expensive method of repairing.

Refinishing of the entire coating system will be dependent upon the type of coating used and the degree of wear on the coating. Most epoxy systems can have a new top coat applied without removing the entire coating. Polished concrete will require re-polishing every few years to maintain the desired finish.

Value vs. Cost

The cost of installing a concrete floor coating system will vary greatly depending upon the system selected, the condition of the floor, and the size of the floor. A typical price range for a basic epoxy coating system starts at approximately $3-$5 per sq. ft., while a higher-end system can cost upwards of $8-$12 per sq. ft. Long-term value considerations will include the durability of the coating system, the frequency of maintenance required, and how long the coating system will retain its aesthetic appeal.

While professional installation will be more expensive than attempting the installation yourself, it will provide you with a warranty that covers you against premature failures and will also ensure that the coating system performs to its maximum potential.

Return on Investment (ROI)

A beautifully decorated garage or workshop increases the resale value of your home and the desirability to potential buyers. Functionally, improved lighting and reduced dusting will make working in the garage or workshop more enjoyable and efficient. Improved functionality can justify the cost of the initial installation and provide you with many years of continued enjoyment.

Permits and Local Ordinance Compliance

Typically, there will be no permit requirements for installing a concrete floor coating system in an existing garage or workshop in Kettering, Ohio. However, if you are going to make electrical changes to your garage to improve lighting, you will need to obtain a permit from the City of Kettering’s Building Department.

Disposal of the Removed Coatings and Waste Materials from Surface Preparation

There are environmental regulations that govern the disposal of removed coatings and waste materials generated during surface preparation. Professional contractors will have the necessary licensing and will follow the proper disposal procedures to ensure compliance with EPA regulations. Homeowners should be aware of these regulations to avoid violating them when performing DIY projects.

Selecting Professional Contractors

Contractors experienced with the conditions of Kettering, Ohio, will know the correct methods for installing a concrete floor coating system in the local climate. Licensed, insured, and bonded contractors will provide you with protection for the duration of the project. Contacting a contractor who recently completed a project in your neighborhood, such as Indian Riffle Park, will give you an idea of their capabilities.

Warranties provided by the manufacturer and guarantees of installation will provide you with long-term protection. Written proposals that clearly define the scope of the project and the costs will help to avoid misunderstandings. Professional contractors will handle the permitting, inspections, and material delivery to facilitate a seamless project execution.

Project Planning and Scheduling

Prior to beginning the project, the contractor will evaluate your site to identify any potential problems that could arise and will assist you in determining the best coating system for your needs. A clear plan and timeline will be developed that considers the application time, weather conditions, and your convenience. Open communication will assure you that the project is proceeding according to your expectations and will meet your satisfaction.

Material purchasing and delivery will be scheduled to avoid delays in the project and to ensure that you receive the freshest products to provide the best possible performance. Professional project management will cause the least disruption to your routine while providing quality workmanship.

Improving Your Kettering Property

A well-installed concrete floor coating system will produce a visually appealing and functional space that complements the residential character of Kettering. Colors and finishes can be coordinated to blend perfectly with your house and landscaping. A professionally installed system will add value to your home and provide a functional space for your hobbies, vehicle maintenance, and storage needs.

A modern garage and workshop space will withstand the extreme temperatures and precipitation of the Midwest while maintaining a beautiful appearance all year round.

At Kettering Concrete Solutions, we understand the special demands of a garage and workshop concrete floor coating in our local environment and conditions. We will guide you through the process of determining the right system for your needs and then professionally install the system to meet your expectations.