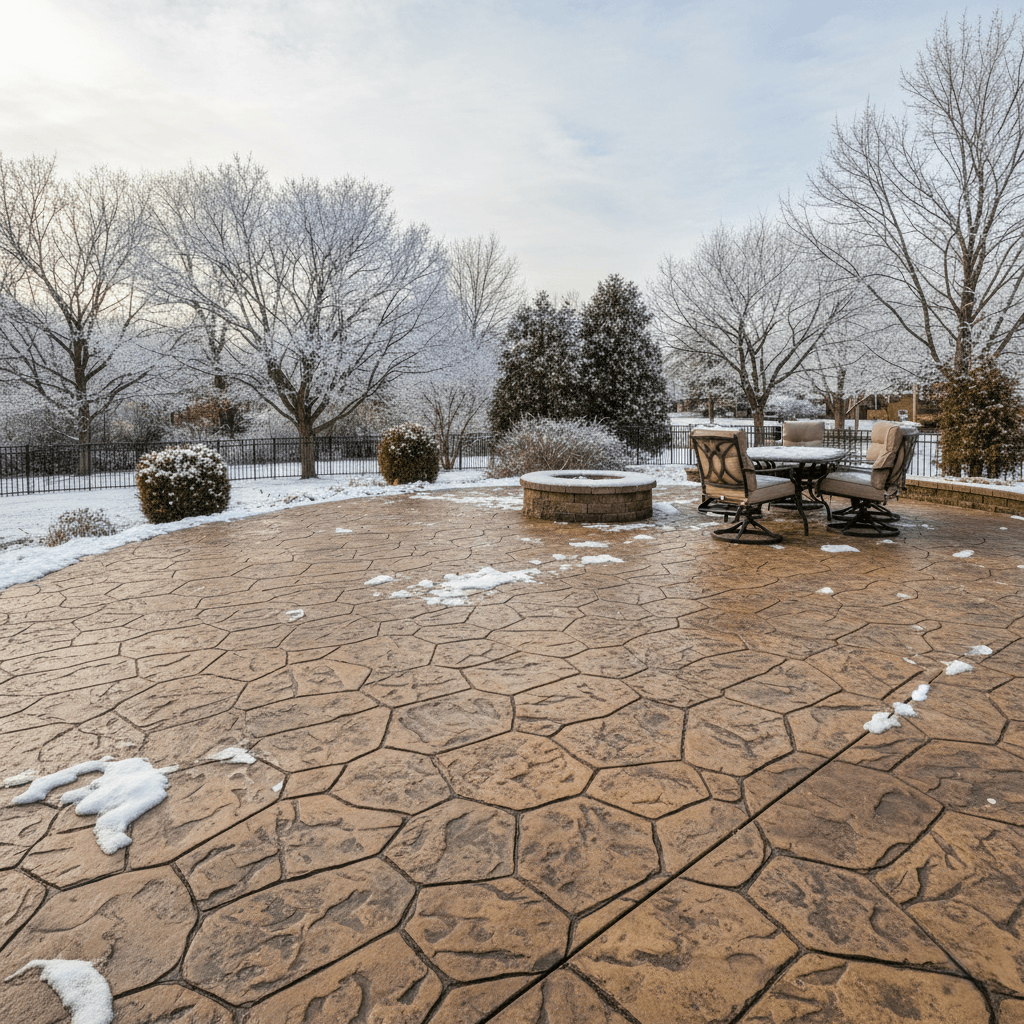

Stamped Concrete in Kettering: Pros & Cons

Stamped Concrete Kettering

Homeowners who are thinking about using stamped concrete on their Kettering homes need to compare the advantages of stamped concrete with the challenges that come with the climate in Ohio. The climate in Ohio is a continental climate, which includes extreme temperatures. Summer temperatures may reach as high as 84° F and winter temperatures as low as 22° F. The extreme temperatures present unique challenges for the installation of decorative concrete, such as stamped concrete. Understanding how freeze-thaw cycles, moisture, and changes in temperature throughout the year impact the performance of stamped concrete will help homeowners achieve success with the long-term installation of their stamped concrete. Proper installation by professionals and appropriate maintenance practices can also help improve the durability of stamped concrete, thereby reducing problems related to weather.

Key Advantages of Stamped Concrete

Stamped concrete has tremendous design flexibility, appealing to residents across Kettering’s many distinct neighborhoods. Modern methods of stamping are capable of replicating natural stone, brick, wood, and tile patterns with great precision. The wide variety of colors available, from subtle earth tones to bold architectural statements, allows for a smooth integration into an owner’s landscape.

A second key benefit is the cost savings relative to natural materials. Professionally installed stamped concrete typically costs 40-60% less than natural stone or brick alternatives, yet still delivers comparable aesthetic appeal. The time to install stamped concrete is dramatically shorter than installing individual pavers or stones, which will reduce both project disruption and labor costs.

Structural Integrity and Durability

If properly installed, stamped concrete performs very well structurally, even in Ohio’s harsh weather. Today’s modern concrete formulations contain the necessary amounts of air-entrainment to resist freeze-thaw damage that normally occurs with other types of materials. Quality installations throughout Kettering, particularly in the Delco Park area and surrounding neighborhoods, have demonstrated more than two decades of dependable performance with few maintenance needs.

High-load-bearing capacity is a feature of stamped concrete that makes it an ideal option for driveways and high-traffic areas. Unlike pavers that can move or settle, monolithic concrete construction retains a constant level of surface elevation. High-quality color hardeners enhance surface density, increasing the material’s ability to withstand wear and weather.

Minimal Maintenance Needs

Compared to other decorative pavement materials, maintenance needs for stamped concrete are extremely low. A simple cleaning using regular pressure washing will remove dirt and organic matter that accumulates on the surface. Periodically, owners need to re-seal (every 2-3 years) their stamped concrete to maintain its original color and protect the surface.

Weed-growth issues associated with paver installations do not exist with a solid concrete surface. Owners can clear snow safely from their stamped concrete driveway without worrying about displacing individual pavers or damaging joint materials. Additionally, stamped concrete resists salt and de-icing chemicals better than natural stone products.

Limitations due to Weather

Challenges related to Freeze-Thaw Cycles

In addition to the potential for freeze-thaw damage, Kettering’s climate experiences approximately 100-120 freeze-thaw cycles annually. As such, this presents the largest threat to stamped concrete installations. When water enters the small cracks or gaps that occur due to inadequate sealing, it freezes and expands inside the concrete. This increases the internal pressure of the concrete, leading to surface scaling, spalling, or cracking over time.

Color hardener systems are widely used to enhance surface density in stamped concrete; however, these systems can also inhibit water’s ability to penetrate the concrete. Trapping moisture underneath a hardened surface can lead to serious problems once freezing occurs. It is crucial that professional contractors balance the desired surface hardness with enough moisture-vapor transmission to prevent internal pressure buildup.

Thermal Expansion and Contraction

The temperature extremes in Ohio (-5°F to 91°F) create a large amount of thermal movement in concrete slabs. Stamped patterns with deep impressions develop additional stresses at the edges of the pattern due to the thermal movement, which can serve as the origin point for cracks. Therefore, the placement of control joints is critical to managing thermal stresses and maintaining the integrity of the pattern.

Dark-colored stamped surfaces tend to absorb more solar radiation than light-colored surfaces, resulting in higher surface temperatures and greater thermal differentials. While light-colored patterns tend to minimize thermal stress, they can also reveal dirt and stains more quickly. Professional designers should carefully select the direction and shade of their stamped concrete to optimize performance.

Considerations for Moisture Management

Ohio’s average annual precipitation of 25 inches, along with the accumulation of snow, necessitates careful planning for moisture management. Proper surface drainage prevents standing water that can contribute to freeze-thaw damage. Patterns created by stamping should be designed so that they do not produce low spots where water can accumulate and freeze repeatedly.

Humidity levels throughout the various climate zones in Kettering affect the curing conditions and long-term performance of the stamped concrete. Summer humidity levels of up to 82% can impede the rate of moisture evaporation from newly installed stamped concrete. Winter conditions, characterized by rapid temperature fluctuations, can cause surface crusting if there is inadequate protection of the curing process.

Seasonal Restrictions for Installations

Weather-related limitations on the timing of installations represent a significant constraint on contractors. Low temperatures (less than 40°F) require the use of special cold-weather concrete admixtures and the application of extended protection measures. Stamping operations can be problematic when the ambient temperature affects the working time and clarity of the pattern definition.

Spring installations in the vicinity of Indian Riffle Park and similar locations must take into consideration soil conditions and groundwater levels. Fall installations require completion before the onset of sustained freezing temperatures. Summer heat can rapidly accelerate the setting time for the concrete, thus requiring experienced crews for optimal results.

Protection and Sealing Requirements

Appropriate sealing is essential to the performance of stamped concrete in Kettering’s climate. Acrylic- or polyurethane-based sealers provide a moisture barrier that allows for vapor transmission. The timing of the application of a sealer is critical to achieving maximum penetration and curing of the sealer. Sealers must strike a balance between enhancing the visual appearance of the stamped concrete and protecting the surface from environmental elements.

Film-forming sealers provide excellent protection from moisture; however, they may become slippery when wet. Penetrating sealers provide better slip-resistance characteristics than film-forming sealers; however, penetrating sealers require more frequent reapplications to achieve optimal protection.

Strategies for Protecting Stamped Concrete During Winter Operations

Exposure to de-icing chemicals and other substances during winter operations presents ongoing threats to stamped concrete surfaces. Sodium chloride and calcium chloride can infiltrate the pores of the concrete, accelerating freeze-thaw damage. Sand and calcium magnesium acetate provide safer alternatives for controlling ice on decorative surfaces.

Techniques for removing snow from stamped concrete surfaces should avoid aggressively scraping the surface, as this can damage the sealed surface or the stamped pattern. Plastic shovels and rubber-edged plows can prevent surface scratching while providing safe working conditions. Rapid removal of snow minimizes the number of freeze-thaw cycles experienced by the stamped concrete.

Design Considerations for Local Climate

The selection of the pattern for stamped concrete significantly impacts long-term performance in Ohio’s climate. Textures with shallow relief are generally more resistant to freeze-thaw damage than deeply textured patterns. Stone and slate patterns generally perform better than wood-grain patterns, which create deep grooves for water accumulation.

Integration of drainage becomes a priority for successful installations. Proper slope design directs water away from buildings and maintains the aesthetic quality of the stamped pattern. Strategically placing control joints is necessary for accommodating thermal stresses while maintaining the integrity of the stamped pattern.

Color and Finish Options

Integral coloring produces superior fade-resistant colors compared to surface-applied color systems. Earth tones and grays are effective at hiding minor surface wear while continuing to reflect heat from the sun. Using multiple colors produces realistic variation and hides minor maintenance issues.

The texture of the finished surface of stamped concrete affects slip-resistance and cleaning ease. Moderate textures provide acceptable traction without creating excessive maintenance challenges. Smooth finishes may be slippery when wet, but are easier to clean during routine maintenance operations.

Performance Expectations Over the Life of the Material

Establishing reasonable performance expectations for stamped concrete helps homeowners make informed decisions regarding their investment in this product. Quality installations generally provide 15-25 years of excellent appearance with proper maintenance. Minor surface wear and some crack development should be anticipated in Ohio’s climate.

Comparing stamped concrete to other materials demonstrates its competitive advantages. Natural stone installations experience significant settling and deterioration of the joints within 10-15 years. Individual pavers may require leveling and replacement of joint sand every 3-5 years in freeze-thaw climates.

Scheduling Maintenance

Regular maintenance is essential to maximizing the longevity and appearance of stamped concrete. Annually inspect and clean your stamped concrete to detect minor issues before they become costly repairs. Regularly seal cracks and reapply spot sealers to prevent moisture infiltration and progression of freeze-thaw damage.

Additional seasonal maintenance activities include preparing your stamped concrete surface for winter and assessing damage caused by winter operations. Clean your stamped concrete thoroughly in the spring to remove de-icing residue and winter debris accumulation. Prepare your stamped concrete for fall by conducting a thorough cleaning and sealer evaluation before the start of the freeze-thaw season.

Cost/Benefit Analysis

Typical costs for initially installing stamped concrete vary from $8-$15 per square foot based upon the complexity of the pattern and the colors selected. These costs compare favorably to the costs of installing natural stone ($15-$25 per square foot). In comparison to other decorative materials, long-term maintenance costs associated with stamped concrete are substantially lower.

For most homeowners, attractive outdoor living spaces will justify the investment in stamped concrete due to the enhanced property value, improved marketability, and buyer appeal throughout Kettering’s residential markets. In general, quality installations of stamped concrete provide a strong return on investment over their service life.

Total Ownership Costs

Total ownership costs include the initial installation cost, routine maintenance costs, and ultimately the cost of replacing or restoring the material. Typically, stamped concrete requires significant restoration after 20-25 years of service compared to 10-15 years for other decorative materials. Average annual maintenance costs for stamped concrete are $0.50-$1.00 per square foot.

Energy Efficiency Benefits

Stamped concrete provides several energy-efficient benefits, including reduced irrigation requirements and reduction of urban heat island effects. Light-colored stamped surfaces reflect significantly more solar radiation than dark-colored asphalt. Also, proper drainage reduces standing water and mosquito-breeding areas around homes.

Importance of Hiring a Qualified Contractor

Utilizing techniques that are suitable for Kettering’s climateise important for the long-term success of stamped concrete installations. Contractors with extensive experience in the local environment and a history of completing successful installations in similar environments are essential for producing quality installations. A contractor’s references from recent installations in the vicinity of the Kettering Recreation Complex, for example, demonstrate their capability to complete similar installations in the same environment. Ensuring a contractor is licensed, insured, and certified by manufacturers assures professional standards and warranty protection.

Evaluation Criteria for Contractors

Contractors who are skilled at producing high-quality stamped concrete installations are those who have a history of producing successful installations in the Kettering environment. Demonstrating contractor knowledge of local soils, drainage, and weather conditions relevant to concrete performance is essential. Reviewing a contractor’s portfolio to determine their skill with specific patterns, colors, and installation challenges is recommended. Providing written proposals that specify the contractor’s plans for mix design, sealing systems, and maintenance requirements is essential to developing a positive relationship with the homeowner and preventing future disappointment.

Current Trends and Future Developments

As advancements continue to be made in the field of concrete technology, the performance of stamped concrete in difficult-to-work-with environments continues to improve. Improved admixtures are being developed to enhance freeze-thaw resistance while maintaining the workability of the concrete required for stamping operations. Newer, longer-lasting sealer formulations are being developed to provide longer service life and better protection against moisture infiltration.

From an environmental perspective, the use of locally produced stamped concrete is preferred over the extraction and processing of quarried stone for decorative purposes, as it reduces the carbon footprint of the material and supports regional economic development. The development of permeable stamped concrete systems addresses stormwater management requirements in new construction.

At Kettering Concrete Solutions, we provide full-service stamped concrete solutions that meet the unique demands of Kettering’s climate. We combine the best practices of stamped concrete installation with the latest materials and maintenance strategies to produce outstanding results that last for years to come in Ohio’s harsh climate conditions.